EMS Electro Static Precipitators

Electrostatic Precipitators(ESP)

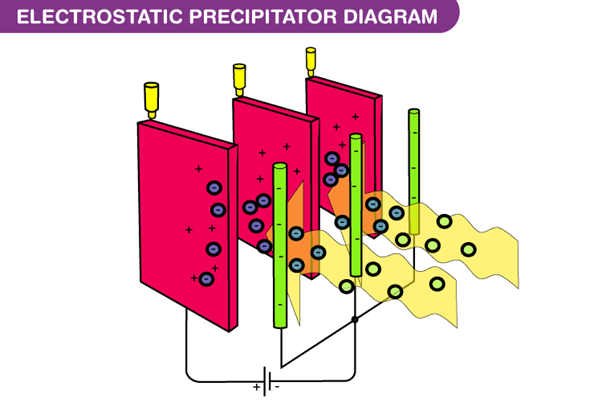

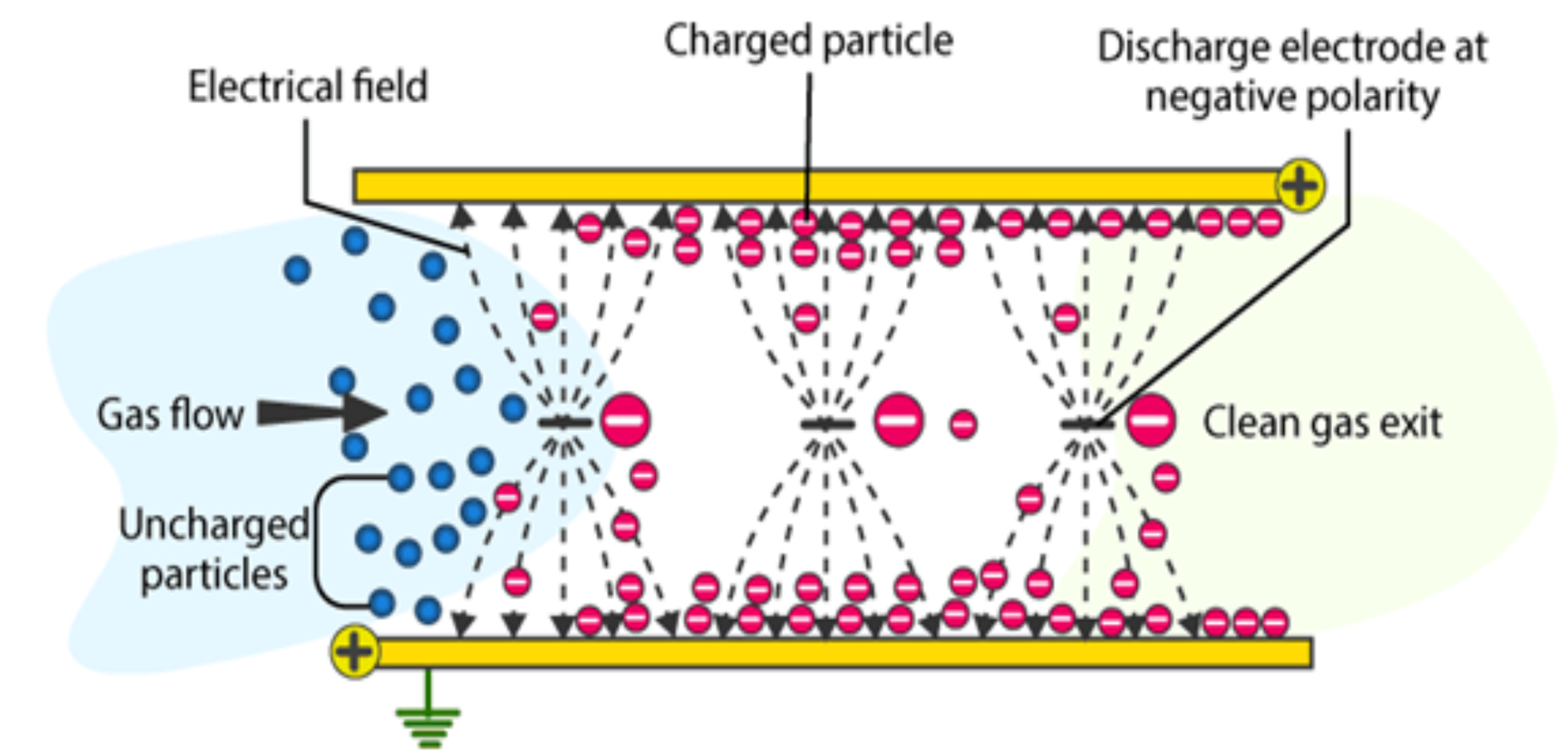

An electrostatic precipitator (ESP) is defined as a filtration device that is used to remove fine particles like smoke and fine dust from the flowing gas. It is the most commonly used device for air pollution control. They are used in industries like steel plants, and thermal energy plants. Technicus is specialized in designing ESP as per the process requirements

Types of Electrostatic Precipitator

There are different electrostatic types, and here, we will study each one of them in detail. Following are the three types of ESPs:

- Plate precipitator: This is the most basic precipitator type that consists of rows of thin vertical wires and stack of vertically arranged large flat metal plates that are placed at a distance of 1cm to 18cm apart. The air stream is passed horizontally through the vertical plates and then through the large stack of plates. In order to ionize the particles, a negative voltage is applied between the wire and the plate. These ionized particles are then diverted towards the grounded plates using electrostatic force. As the particles get collected on the collection plate, they are removed from the air stream.

- Dry electrostatic precipitator: This precipitator is used to collect pollutants like ash or cement in a dry state. It consists of electrodes through which the ionized particles are made to flow through and a hopper through which the collected particles are extracted out. The dust particles are collected from a stream of air by hammering the electrodes.

- Wet electrostatic precipitator: This precipitator is used to remove resin, oil, tar, paint that are wet in nature. It consists of collectors that are continuously sprayed with water making the collection of ionized particles from the sludge. They are more efficient than dry ESPs.

- Tubular precipitator: This precipitator is a single-stage unit consisting of tubes with high voltage electrodes that are arranged parallel to each other such that they are running on their axis. The arrangement of the tubes could either be circular or square or hexagonal honeycomb with gas either flowing upwards or downwards. The gas is made to pass through all the tubes. They find applications where sticky particles are to be removed.

Advantages and Disadvantages

Advantages of electrostatic precipitator:

- The durability of the ESP is high.

- It can be used for the collection of both dry and wet impurities.

- It has low operating costs.

- The collection efficiency of the device is high even for small particles.

- It can handle large gas volumes and heavy dust loads at low pressures.

Disadvantages of electrostatic precipitator:

- Can’t be used for gaseous emissions.

- Space requirement is more.

- Capital investment is high.

- Not adaptable to change in operating conditions.

One Stop Solution for All Your Epc Requirements

We pride ourselves on our customer-focused approach and provide a one-stop solution for all your EPC requirements.

Our Clients